The importance of deflocculants in pottery

Contents

1- Deflocculants: definition and role in glazes and casting slips

2- Types of deflocculants commonly used in pottery

3- Bentonite and vinegar

4- Methods for measuring and applying deflocculants

5- Effects of deflocculants on ceramics

6- Problems and solutions in the use of deflocculants

Introduction

Have you ever heard of deflocculants? These additives can modify the consistency of glazes and casting slips, making them easier to work with. They can prevent “hard pan”, the sedimentation of glazes as heavier particles settle into a dense layer, a problem frequently encountered by potters in glazes and slips.

At Créamik, we teach our students not only to throw and to make and apply their own glazes, but also how to understand and use these additives. This helps them solve common problems such as shrinkage and cracking.

In this article, we discuss the role of deflocculants, how they work, and how they improve the quality and aesthetics of glazes.

Deflocculants: definition and role in ceramic glazes and casting slips

In our previous article, we looked at how to measure the density of glazes. Depending on the raw materials in a glaze, a “hard pan” can form at the bottom of the bucket or container. Measuring the density of a glaze is only possible if it is in a stable suspension.

In practice, potters are regularly confronted with hard pan, as in the sedimentation of the glaze. In just a few hours, the glaze can settle and stick to the bottom of the bucket, and it’s very difficult to get it back into suspension. The solution? Deflocculants. But before going any further, let’s understand an essential concept: viscosity.

- Viscosity: a key property in ceramics

Viscosity is the measure of a fluid’s resistance to flow. In ceramics, it is crucial for managing the consistency of slips and glazes. High viscosity means a thicker, less fluid texture, while low viscosity indicates a more liquid, fluid texture. Viscosity influences not only the ease of glaze application and slip casting, but also the quality and final appearance of ceramic pieces.

- What is a deflocculant?

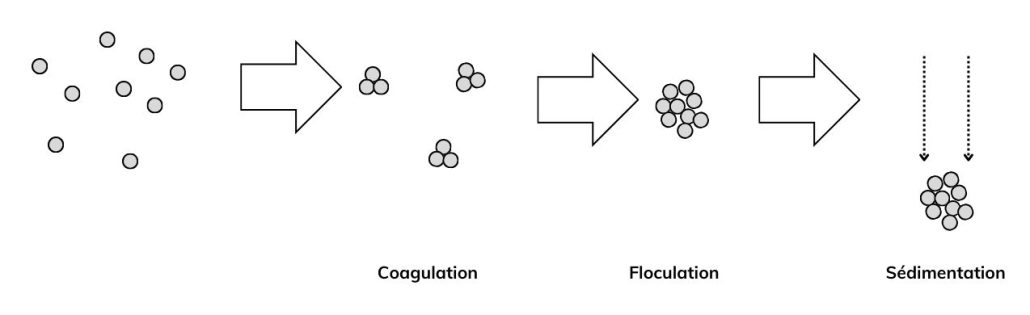

A deflocculant is a chemical agent used to reduce particles’ attraction in liquid suspensions, such as glaze and slip. In simple terms, it helps to disperse solid particles evenly in a liquid, preventing settling.

- How do they work chemically?

Chemically, deflocculants work by modifying the surface charge of particles in a suspension. Most solid particles in slip carry a natural electrical charge, which can lead to agglomeration. When a deflocculant is added, it changes the surface charge of these particles, making them more uniformly charged. This increases the repulsion between particles, preventing them from sticking together. This action modifies the suspension’s viscosity, making it easier to work with.

- Impact on casting slip texture and viscosity

By preventing particle agglomeration, deflocculants enable the slip to maintain a smooth, homogeneous consistency. They help avoid excessive water addition and make manipulation of the slip easier for casting. When used in glazes, deflocculants promote optimal viscosity, enabling better control, better finish and, consequently, more attractive pieces.

Types of deflocculant commonly used in ceramics

There are several types of deflocculant commonly used by potters, each with its own advantages and disadvantages.

Sodium silicate

Sodium silicate, often referred to as water glass or liquid glass, is a deflocculant widely used in ceramics, both for slip and glaze. It effectively reduces viscosity and facilitates slip casting, as well as improving fluidity and stability in glazes.

Advantages: Sodium silicate is not only readily available and cheap, but also highly effective in small quantities. It works quickly to disperse particles, ensuring a smooth, even application.

Disadvantages: Its alkaline nature, while beneficial for particle dispersion, can affect the durability of plaster moulds. If used in excess, it can make slip and glazes too fluid, making them difficult to handle. It should therefore be used in precisely measured quantities.

Optapix and Dolapix

These two products are brands of synthetic deflocculant, frequently used as alternatives to sodium silicate for both slip and glaze preparation. They are easier to obtain, and more commonly used, in Europe and the US than in the UK.

Advantages: Optapix and Dolapix are less alkaline than sodium silicate, therefore less aggressive to plaster moulds. For slip, they provide better viscosity control. For glazes, they ensure a more uniform application, thus better quality.

Disadvantages: these deflocculants can be more expensive than sodium silicate. They also require addition in precise quantities to avoid excessive deflocculation, which could compromise both the stability and consistency of slips and glazes.

The use of Optapix and Dolapix is common in ceramics. However, the use of a deflocculant depends on several factors, including the composition of the clay, the type of glaze used, and the desired properties of the final piece. It is therefore important to carry out tests to determine the amount of deflocculant to be used.

Bentonite and vinegar

- Bentonite

The best-known deflocculant is bentonite, a highly absorbent fine clay. It should be added to the other glazing ingredients – without exceeding 2% of the total – before the water is added and everything is meticulously mixed.

Suspending agents must be used with care and in precise quantities. If used in excess, they can make slips too thick and glazes difficult to apply. Testing is necessary to find the quantities that will produce the most workable and best quality slips and glazes.

- Vinegar

The use of vinegar in glazes is a rather unconventional practice, but it can have certain advantages:

– Vinegar, being acidic, will lower the pH of a glaze. This will affect how the glaze components interact. A few drops can thicken the glaze; too much will do the opposite.

– As with any additive, start with small quantities and note the effects on glazes after firing. Bear in mind that the addition of vinegar (or any acid) can interfere with certain chemicals present in the glaze and so it is advisable to test before applying to large or important pieces. Vinegar is generally added drop by drop and thoroughly mixed with the glaze.

Methods for measuring and applying deflocculants

The correct use of deflocculants is essential to obtain the desired consistency in slip and glaze.

- Techniques for determining the appropriate quantity of deflocculant

A common method is the viscosity test. This can be done by preparing a small quantity of slip or glaze and gradually adding the deflocculant, while monitoring the liquid’s consistency. Another indicator is the way the suspension flows from a mixing tool or spatula – it should form a continuous ribbon without breaking.

- Practical tips for adding and mixing deflocculants in slips and glazes

For casting slips, make sure the suspension is free of lumps before adding a deflocculant. For glazes, constant stirring is essential to maintain uniform particle distribution. After adding the deflocculant, let the slip or glaze stand for a while to observe any changes in consistency.

It is important to take precise notes on the quantities used in order to reproduce the same consistency in future batches. Experience and observation will play a major role in refining this technique.

Effects of deflocculants on ceramic properties

The use of deflocculants in ceramics, whether in slip or glaze, has a noticeable impact on several features of ceramics, such as shrinkage, texture and the durability of finished pieces.

- Impact on shrinkage, texture and durability

By modifying the distribution and orientation of particles, deflocculants can help minimize uneven shrinkage. In addition, good slip and glaze consistency contributes to a smoother and homogeneous surface.

As far as durability is concerned, applying a glaze evenly, aided by the correct use of deflocculants, can improve the resistance of the ceramic surface to marking, scratching or chipping.

- Glazing and firing considerations

When glazing, the use of deflocculants influences the way the glaze adheres to the clay surface. Optimized viscosity enables a more uniform application, avoiding problems such as drips or unevenness. This is particularly relevant for complex glazing techniques.

During firing, good slip and glaze stability will avoid unpleasant surprises such as colour changes, cracking or surface defects after firing.

Problems and solutions when using deflocculants

When using deflocculants in slips and glazes, certain specific problems may arise, requiring appropriate solutions.

– Formation of lumps in slip:

When lumps form in slip it generally indicates poor particle dispersion. To remedy this, careful sieving or additional mixing may be needed.

– Glaze drips:

This can be a problem during application, particularly if the viscosity is not optimal. To avoid this problem, it is advisable to apply the glaze in thinner layers. In addition, allowing sufficient drying time between coats can prevent the glaze from running and building up unevenly on the piece.

Conclusion

Over the years, at Créamik, we have explored both traditional and contemporary techniques, as shown in this article on deflocculants. The recent creation of our own casting slip illustrates the ongoing interaction between science and art in ceramics. Understanding additives, such as deflocculants, greatly enriches our practice and enables us to solve practical problems. The need to strike a balance between fluidity and stability, between texture and durability, testifies to the complexity of our craft.

By sharing this knowledge and experience, we hope to inspire our students, and all our readers, to experiment confidently with the subtleties of the materials they use. Ceramics requires constant discovery, expertise, analysis and experimentation… Happy learning!

Resource centre

animated by Matthieu Liévois,

potter-ceramist for over 40 years and founder of the Creamik School

Find all the courses

Keywords

Don’t miss any more news from the Créamik school!